Lightweight Components, Easy to Transport and Install

the elements used in dry systems are lightweight, and being prefabricated and modular they facilitate transport and make both installation and replacement quick

Excellent Thermal-Acoustic Performance

also achieved through the installation of sound-absorbing and heat-insulating sandwich panels that form the building enclosure

Durable and Healthy Structures

Steel dry constructions have a higher fire resistance than conventional constructions, and are not subject to corrosion and moisture, due to the inherent characteristics of this material

High Seismic Response

Given the deformation capacity and high ductility of materials such as steel, these systems react naturally to seismic actions, better than traditional materials

Low Impact On The Environment

as the process is very precise and waterless, the site will be less prone to waste and refuse, so the environmental impact will also be lower

Speed of Execution

working times and stages can be fairly well predicted, limiting downtime to a minimum

Design Versatility

Dry systems can adapt to different architectural forms and design requirements

Quality Control

dry construction by means of certified installation cycles reduces uncertainties and errors on site, and improves the final quality of the artefact

Offsite construction is the future of building industry.

The Light Steel Framing system is an integral part of off-site technologies where the parts are manufactured in a factory controlled environment prior to on-site installation.

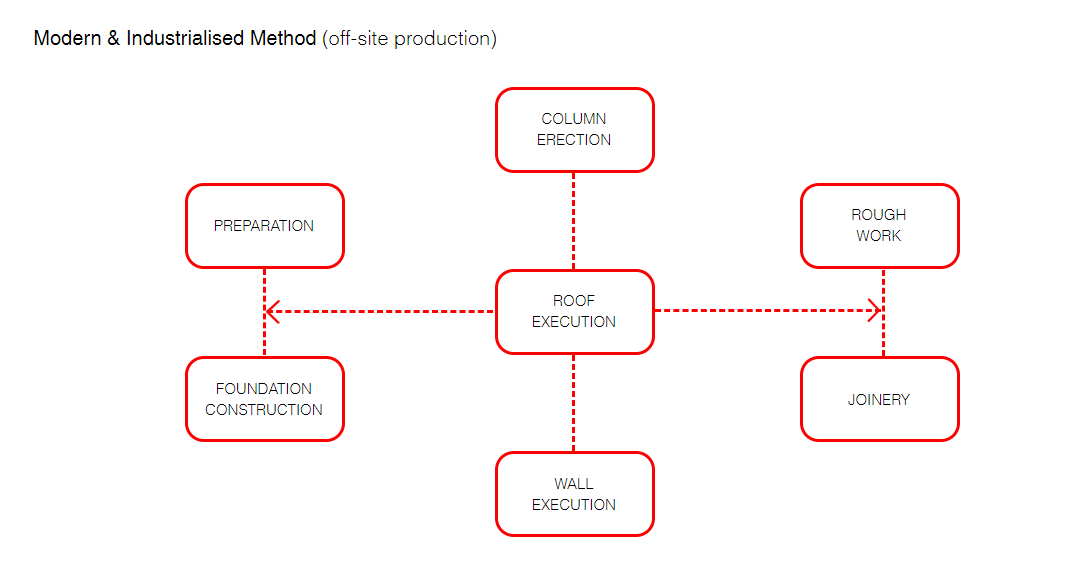

The principle on which off-site construction is built is the industrialisation of processes and building solutions, that increasingly result in factory processing, speeding up and optimising all worksite activities

Prefabricated buildings, which integrate dry construction with the light steel frame construction system, are fast to execute, offer more safety at the worksite, reduce the environmental impact, guarantee energy efficiency and acoustic comfort. In addition, all buildings built with this technique are earthquake-proof.

In today’s building scenario, where it is necessary to reconcile construction speed, cost-effectiveness and a low environmental impact, dry construction is the answer to the current qualitative and performance requirements of the construction market.

Construction Method Optimisation

Construction processes can be slow, and in some cases in need of optimization.

In the construction world, it is not uncommon to see project delays and cost overruns. Light Steel Framing systems employ a more optimised construction process by allowing different vendors to be carry out work in parallel rather than in consecutive stages. This significantly reduces build time and therefore cost.

Benefits of optimised project techniques include better value through improved delivery times; higher-quality relationships, processes, communications, documents, and construction; safer workplaces; more efficient use of resources; less waste of time and money; and much more effective use of money invested in projects.